News

NewsWhat is High Speed Drilling Machine

What is High Speed Drilling Machine

Introduction:

In the realm of precision engineering, the rapid pace of technological evolution continues to reshape industries. One such evolution is the rise of high-speed drilling machines, a revolutionary tool that has transformed the landscape of drilling operations. Trinkle Enterprise, a pioneering name in engineering solutions (https://www.trinkle-tw.com/en-US/), stands at the forefront of this innovation, offering cutting-edge high-speed drilling machines that redefine efficiency, accuracy, and productivity.

What is a High-Speed Drilling Machine and How Does it Work:

At its core, a high-speed drilling machine is a mechanical marvel engineered to execute drilling operations at significantly accelerated rotational speeds. Unlike conventional drilling machines, high-speed variants boast the ability to perform precise drilling tasks with unmatched rapidity. This feat is achieved through intricate mechanisms that optimize the interaction between the cutting tool and the workpiece.

Benefits of Using a High-Speed Drilling Machine:

The advantages of employing a high-speed drilling machine from Trinkle Enterprise are multifaceted. These benefits include:

- Enhanced Productivity: High-speed drilling machines complete tasks in a fraction of the time, boosting overall productivity.

- Superior Surface Finish: The high rotational speeds lead to smoother hole surfaces, crucial for industries demanding impeccable finishes.

- Extended Tool Life: Reduced cutting forces and heat generation result in prolonged tool life and decreased operational costs.

- Precision Redefined: High-speed drilling machines deliver unparalleled accuracy, vital for applications requiring pinpoint precision.

- Versatility: These machines effortlessly navigate a spectrum of materials, underscoring their adaptability and versatility.

Different Types of High-Speed Drilling Machines:

Trinkle Enterprise offers a diverse array of high-speed drilling machines, each tailored to specific industry demands. These include:

- Bench Drill Presses: Ideal for smaller tasks, these stationary machines are perfect for precision drilling.

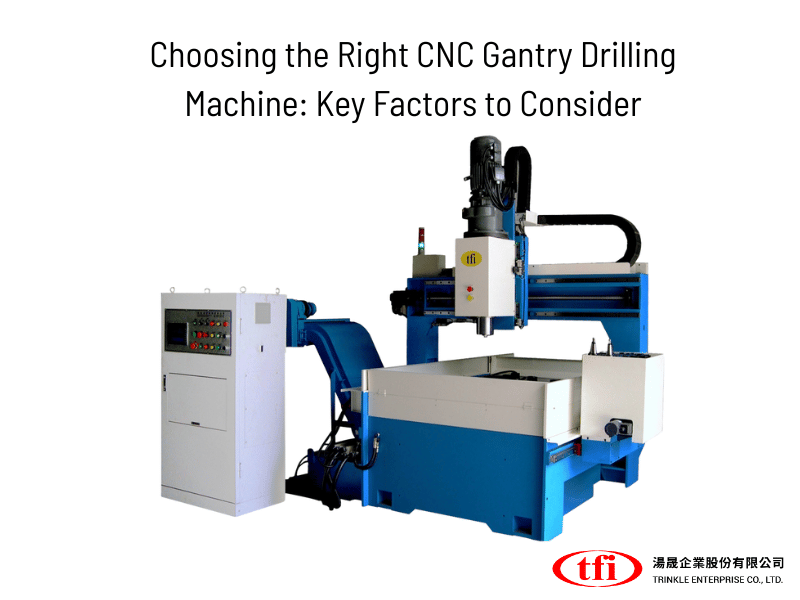

- CNC Drill Machines: Automation meets high speed in these computer-controlled powerhouses, ensuring precise and repeatable drilling operations.

- Magnetic Drills: A portable solution, utilizing electromagnetic force for stability, particularly suitable for onsite drilling needs.

- Radial Arm Drills: These versatile machines allow drilling at various angles and positions, perfect for complex drilling scenarios.

Essential Components in a High-Speed Drilling Machine:

The engineering prowess of Trinkle Enterprise is showcased through the critical components that constitute a high-speed drilling machine. These include the high-speed spindle, advanced cooling and lubrication systems, robust column and base structures, and precision control mechanisms.

Here are the key components that make up a high-speed drilling machine:

1. High-Speed Spindle:

The heart of a high-speed drilling machine is its spindle. It's responsible for holding and rotating the drill bit or cutting tool at the desired speed. High-speed spindles are engineered with precision bearings and balanced to minimize vibration and runout. They are often equipped with powerful motors capable of sustaining the high rotational speeds required for efficient drilling.

2. Advanced Cooling and Lubrication Systems:

The rapid rotation of the drill bit generates heat, which can adversely affect both the tool and the workpiece. Advanced cooling and lubrication systems are integrated to dissipate heat and ensure smooth cutting. These systems typically involve a combination of coolants and lubricants that are accurately delivered to the cutting area. This helps prolong the life of the cutting tool, enhance hole quality, and prevent material deformations due to excessive heat.

3. Column and Base Structure:

The column and base provide stability to the entire machine. In high-speed drilling, stability is critical to achieving accurate results. Trinkle Enterprise's machines feature robust column and base structures constructed from high-quality materials. These components are designed to absorb vibrations, minimize deflection, and maintain rigidity during the drilling process.

4. Precision Control Mechanisms:

High-speed drilling demands precise control over various parameters, such as rotational speed, feed rate, and depth. Modern high-speed drilling machines from Trinkle Enterprise often feature advanced control systems, including digital displays and programmable interfaces. These interfaces allow operators to fine-tune drilling parameters, ensuring consistent and accurate results across multiple tasks.

5. Tool Changer (for CNC Machines):

In the case of CNC high-speed drilling machines, an automatic tool changer is a critical component. It enables the machine to switch between different drill bits or cutting tools without manual intervention. This feature enhances efficiency, reduces downtime, and expands the machine's capabilities by accommodating various drilling requirements within a single setup.

6. Safety Features:

High-speed drilling machines incorporate safety features to protect both the operator and the machine. Emergency stop buttons, safety shields, and interlocks are standard components that prevent accidents and injuries. Trinkle Enterprise prioritizes operator safety by adhering to stringent safety standards and incorporating advanced safety mechanisms.

7. Digital Feedback Systems:

To ensure precision, some high-speed drilling machines employ digital feedback systems. These systems provide real-time information about the drilling process, such as depth and position. This feedback is used to monitor and adjust drilling parameters, resulting in accurate hole placement and consistent quality.

8. Material Handling Mechanisms:

For larger or more complex operations, material handling mechanisms may be integrated. These systems assist in moving heavy workpieces, enabling accurate positioning and efficient drilling.

Factors to Consider When Selecting a High-Speed Drilling Machine:

Selecting the right high-speed drilling machine necessitates a holistic approach. Factors such as material type, required tolerances, drilling depth, and available workspace must be meticulously evaluated. Trinkle Enterprise provides expert guidance to ensure the optimal machine selection for every unique requirement.

Common Applications of a High-Speed Drilling Machine:

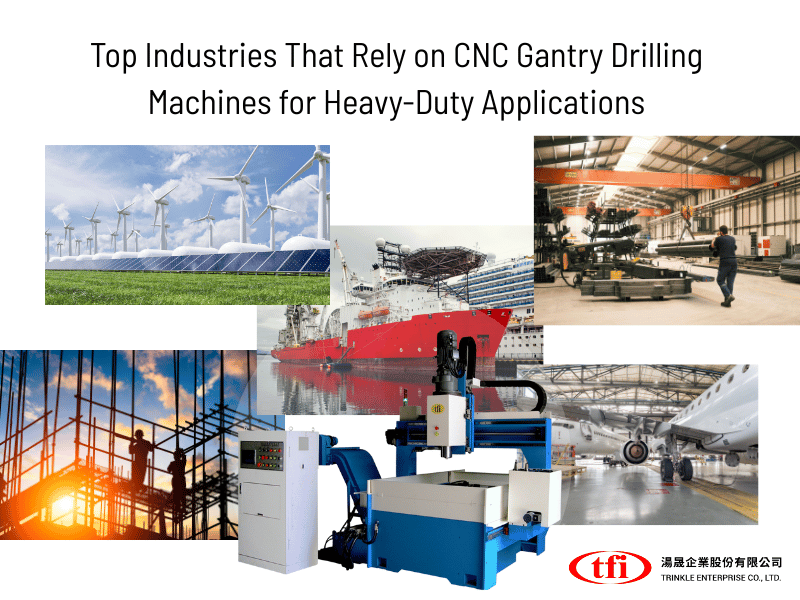

The applications of Trinkle Enterprise's high-speed drilling machines span a multitude of industries:

- Aerospace: Crafting precision holes in aerospace components with stringent quality demands.

- Automotive: Enabling efficient and accurate drilling in the production of automotive parts.

- Electronics: Ensuring meticulous drilling in intricate electronic circuit boards.

- Medical Devices: Precision drilling for medical implants and instruments.

- Metal Fabrication: Empowering efficient metalwork through rapid, accurate drilling.

Conclusion:

As industries embrace the era of high-speed drilling machines, Trinkle Enterprise remains an unwavering partner, providing cutting-edge solutions that define efficiency and precision. With a steadfast commitment to innovation and excellence, Trinkle Enterprise propels drilling operations into a new dimension of speed and accuracy, empowering industries to reach unparalleled heights of productivity and quality.