News

NewsTop Industries That Rely on CNC Gantry Drilling Machines for Heavy-Duty Applications

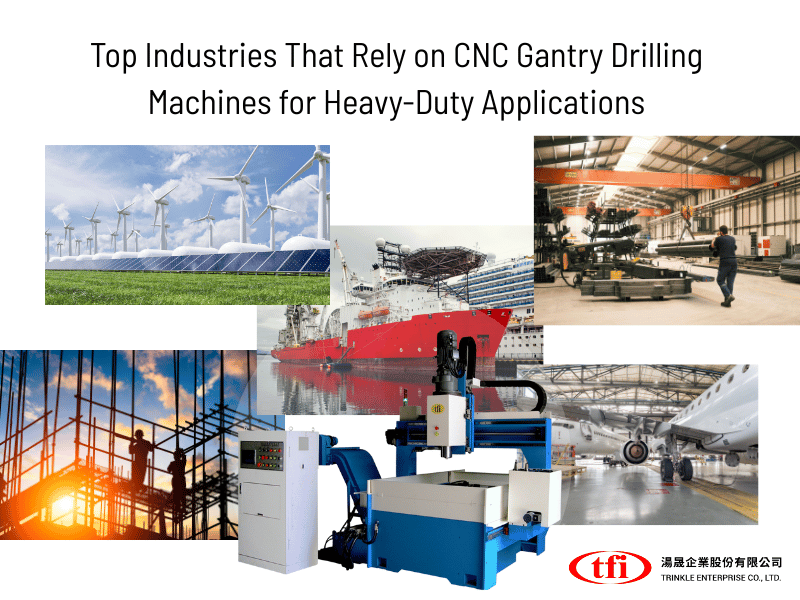

Top Industries That Rely on CNC Gantry Drilling Machines for Heavy-Duty Applications

Introduction

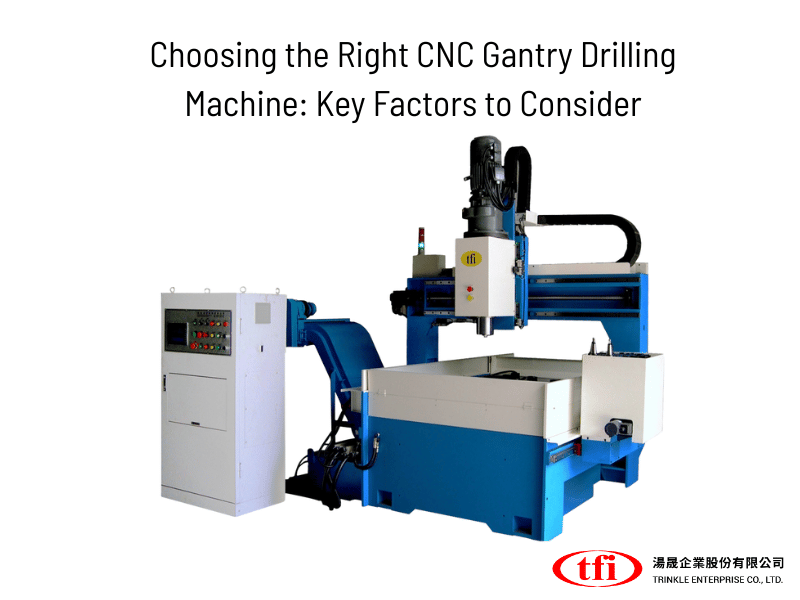

CNC Gantry Drilling Machines have become essential equipment in industries that require precise, heavy-duty drilling of large steel plates, beams, and structural components. With their ability to handle massive workpieces, perform complex drilling patterns, and deliver high-speed automation, these machines are revolutionizing modern industrial manufacturing.

At Trinkle Enterprise Co., Ltd., we specialize in the design and production of high-performance CNC Gantry Drilling Machines that serve a wide range of applications. In this article, we'll highlight the top industries that rely on CNC gantry drilling machines and explore why they are a crucial part of their production lines.

________________________________________

Steel Construction and Infrastructure

One of the largest and most consistent users of CNC gantry drilling machines is the construction and infrastructure industry. From high-rise buildings to bridges and stadiums, steel structures rely on accurately drilled beams and plates to ensure stability and safety.

Why CNC Gantry Drilling Machines Matter:

- They allow precise bolt hole drilling in H-beams, I-beams, and steel plates.

- They support large-scale fabrication with automated batch processing.

- They help reduce human error and speed up steel assembly at construction sites.

Example:

Fabricating a skyscraper framework with thousands of identical drilled holes is nearly impossible manually. CNC gantry machines ensure every hole is placed exactly where it needs to be.

________________________________________

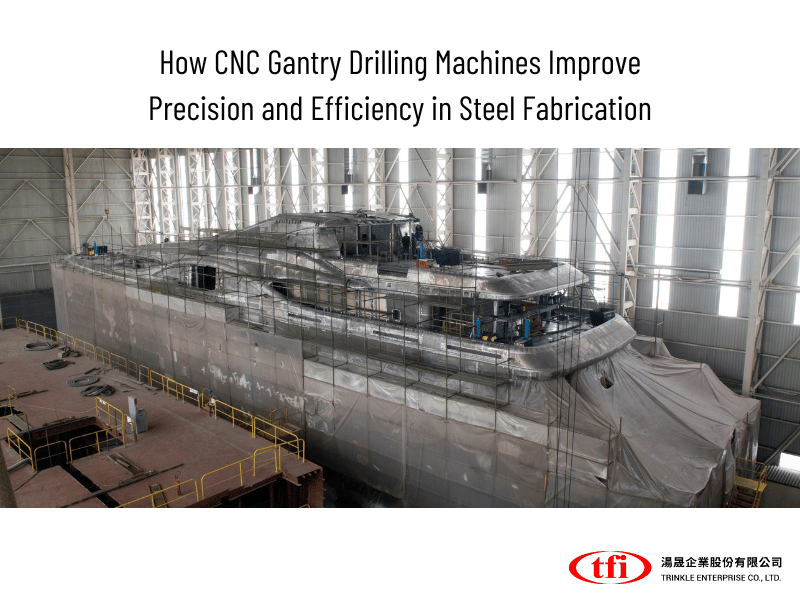

Shipbuilding and Marine Engineering

In the shipbuilding industry, massive steel components need to be processed with a high level of accuracy. These include the hull sections, decks, and internal structural supports.

Why CNC Gantry Drilling Machines Matter:

- They handle oversized and thick steel plates required for ship structures.

- They support multi-hole and deep-hole drilling, essential in marine-grade steel.

- They help maintain tight tolerances and smooth assembly during shipbuilding.

Example:

In large vessels such as cargo ships or naval ships, CNC drilling machines are used to drill thousands of precision holes across steel hull sections for efficient welding and bolting.

________________________________________

Heavy Machinery and Equipment Manufacturing

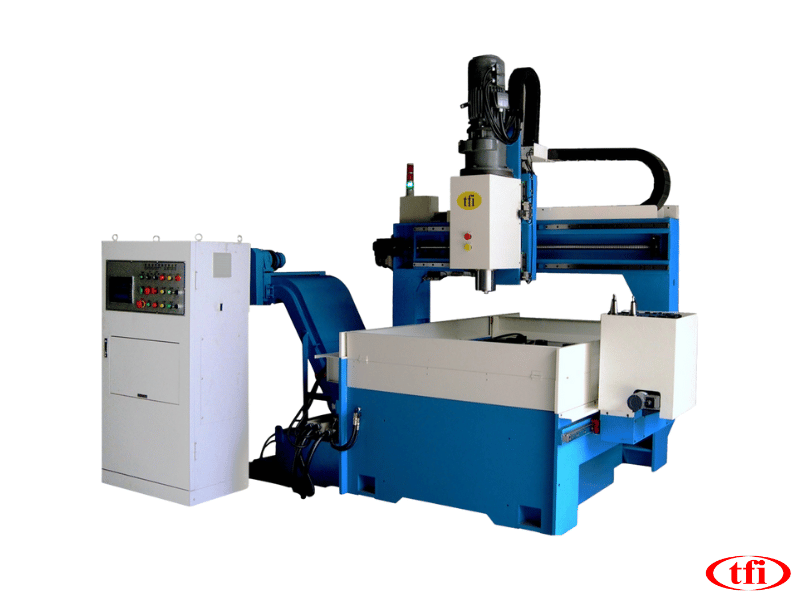

CNC Gantry Drilling Machines are a staple in the heavy machinery sector, where the size and weight of components demand powerful, high-precision equipment.

Why CNC Gantry Drilling Machines Matter:

• They process large and heavy-duty parts like chassis frames and mounting bases.

• Their multi-axis systems allow for complex and angled hole drilling.

• They reduce setup times and enable large-volume production.

Example:

Manufacturers of mining equipment, cranes, bulldozers, and presses use gantry-type drilling machines to drill structural parts that must endure extreme forces.

________________________________________

Wind Energy and Renewable Power

The wind energy industry uses tower flanges, base plates, and nacelle structures that require precise drilling for assembly. CNC gantry drilling ensures exact alignment of bolt holes, which is critical in resisting wind stress over long periods.

Why CNC Gantry Drilling Machines Matter:

- They ensure uniform bolt hole spacing on circular and flat surfaces.

- They can handle large diameters and thick plates, typical in turbine structures.

- They improve assembly speed and safety for wind towers.

Example:

A wind turbine tower can exceed 100 meters in height. The base plates drilled with CNC gantry machines ensure each segment connects securely, minimizing vibration and increasing service life.

________________________________________

Aerospace and Defense Manufacturing

Precision and consistency are critical in aerospace and defense. Structural parts, such as fuselage frames, support beams, and mounting panels, require exact hole placement with zero tolerance for error.

Why CNC Gantry Drilling Machines Matter:

- They offer micron-level accuracy for high-performance metal components.

- CNC systems enable repeatable production of aerospace parts.

- They reduce error risk in multi-material and alloy plate processing.

Example:

In aerospace projects, every drilled hole is a potential stress point. Gantry drilling machines eliminate manual deviation, ensuring safety-critical components meet strict standards.

________________________________________

Conclusion

CNC Gantry Drilling Machines are indispensable in industries that demand powerful, precise, and high-speed drilling for large and complex components. From skyscraper skeletons and ship hulls to wind towers and aircraft structures, these machines empower manufacturers to produce better, faster, and safer results.

At Trinkle Enterprise Co., Ltd., we design CNC Gantry Drilling Machines that meet the demanding standards of today’s leading industries. Whether you're in construction, marine, energy, or defense, our machines are built to handle your toughest fabrication challenges.

Discover more about our CNC Gantry Drilling Solutions at Trinkle Enterprise Co., Ltd..