News

NewsHow to Choose the Best Drilling Machine | Buying Guide 2022

How to Choose the Best Drilling Machine | Buying Guide 2022

For the best return on your investment, what type of drilling machine should you upgrade from? Which do you prefer: a tool that runs on batteries or requires recharging regularly? It's important to know whether you're working with masonry or wood.

Using a drill, a person can cut through metal, wood, or other materials by making holes. The drill bit, the drilling machine, cuts the material as it travels through the hole. A Morse taper or chuck secures the cutting tool in the drill.

How do you know which drilling machine to purchase?

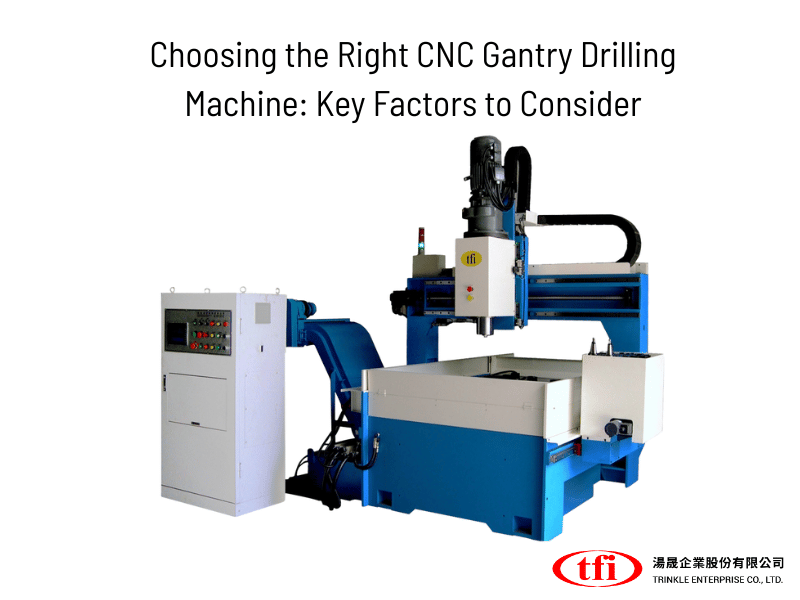

Different drilling machines are available, including portable magnetic drilling machines, CNC plate drilling machines, and large bridge plate drilling machines. You need to consider your work environment before deciding on a drill.

First of all, depending on the materials you have to drill, the diameter and depth of the holes will not be the same. The manufacturer usually provides the maximum diameters and depths for each material.

Another factor to consider is the drill's power. You'll be able to drill through concrete more quickly if you have a power drill.

The drill's power determines the speed at which it can be used. Too fast can damage the drill bit in certain materials, such as metals. Therefore, we recommend using an electronic speed control drill for this type of material.

Finally, a cordless portable drill's voltage should be considered. Batteries that have a higher voltage are stronger.

Types of Drilling Machines:

- Bench Drill Press: A bench drill press is a stationary drilling machine mounted on a workbench or stand. It consists of a vertical column, a motor, and a drill head that can be lowered or raised for drilling operations. It is commonly used for drilling holes in small to medium-sized workpieces.

- Pillar Drill: Similar to a bench drill press, a pillar drill is a larger and more powerful version. It is also mounted on a floor-standing pillar or column. Pillar drills are used for heavier drilling tasks and offer more features and capabilities compared to bench drill presses.

- Radial Arm Drill: A radial arm drill has a long horizontal arm that can be rotated around a vertical column. This type of drill allows drilling operations to be performed at various positions and angles. It is commonly used for drilling large and heavy workpieces.

- Magnetic Drill: A magnetic drill, also known as a mag drill, is a portable drilling machine that uses a strong electromagnetic base to adhere to metal surfaces. It is commonly used in construction, metal fabrication, and maintenance tasks where it is not possible to use a bench or floor-mounted drill.

- Portable Drill: Portable drills, such as corded or cordless hand drills, are handheld drilling machines that are widely used for a variety of applications. They are lightweight, compact, and versatile, making them suitable for drilling holes in various materials, including wood, metal, and plastic.

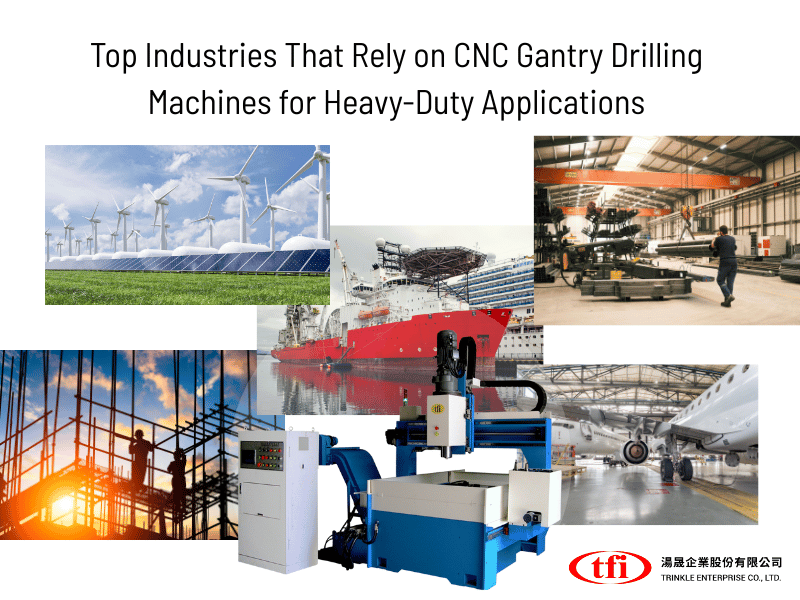

- CNC Drill: CNC (Computer Numerical Control) drills are automated drilling machines that are controlled by computer programs. They are capable of precise and repetitive drilling operations and are commonly used in manufacturing processes where accuracy and efficiency are critical.

- Deep Hole Drill: Deep hole drills are specifically designed for drilling deep holes with high length-to-diameter ratios. They typically have special features to handle the challenges of deep-hole drilling, such as chip evacuation and coolant delivery systems.

- Gun Drill: Gun drills are specialized drills used for deep hole drilling applications. They feature a long, straight flute and are designed to produce deep, straight holes with excellent precision and surface finish.

A 3-Step Guide to Choosing the Right Drilling Machine:

There are a variety of different types of drilling machines on the market, so you'll need to do some research before making a purchase.

For your ease, we've compiled a detailed guide:

1. Consider Your Drill's Purpose Before You Purchase It

Before buying a drill, you must determine what you intend to use it for.

- What surfaces will you need to drill into to complete the project?

- If so, do you need to be able to hold it at a specific angle or position?

- Will it require a lot of physical exertion, such as climbing ladders or traversing uneven ground?

- How long will you be using your drill at a time?

A drill's performance will be improved by being able to answer questions such as these.

2. Choose the Right Drilling Machine for Your Needs.

A drill driver is the most common type of drill used to make holes and drive, tighten, or loosen screws into metal, wood, or other materials.

Drills: These are used to make holes and go, tighten, or loosen screws into metal, wood, or other materials. Stone, masonry, and concrete, on the other hand, are typically beyond their capabilities.

Hammer Drills: A hammer drill can move in and out in a hammer-like motion in addition to spinning. Boreholes in extremely dense materials like stone, concrete, and masonry with the additional force it provides.

When working with wood, avoid using a hammer drill as it can cause damage to the material. When working with hammer drills, wear earplugs to protect your ears from the high decibel noise they produce.

Impact driver: When it comes to driving screws, bolts, and nuts into metal and wood at a high rate of speed, impact drivers are the way to go. You can't interchange drill bits between impact drivers (which have hexagonal sockets) and hammer drills (which have rectangular sockets). Impact drivers, like hammer drills, produce a lot of noise. That necessitates the use of earplugs!

However, if you're working with larger screws or more complex tasks, you should think about switching to a different screwdriver style (like a pistol grip).

3. Make a Choice Between a Corded and a Cordless Drill

Cordless Drills are more versatile than corded drills because they are smaller, lighter, and easier to use.

Cordless Drilling Machine

Consider the following when purchasing a cordless drill:

- Power: You'll need to pay attention to voltage and torque when it comes to power. For the most part, higher voltage equals greater drilling power. While lower (7.2V) and higher (20V) options exist for cordless drills, 18V is the most common.

- Newton-meters are the units used to measure torque (Nm). Some drills allow you to adjust the torque settings to use more or less torque depending on the type of material you're working with.

- Speed: Rotations per minute will be used to quantify speed. While many drills have two speeds, finding a drill with variable speeds (up to 1,000rpm) can give you more control.

- Batteries: Lithium-ion is one of the most popular battery types today, as it charges faster, lasts longer, and is lighter than other types like NiCd (Nickel-Cadmium). Lithium-ion batteries, on the other hand, offer a continuous discharge until the battery is dead.Attention should focus on the battery charger and the battery's Amp hour. Some chargers can recharge a battery in just 15 minutes. Others will require three hours of your time, which can significantly impact your output. Another important metric that tells you how much storage space a battery has. For the most part, the higher the AH value, the longer the battery will last.

Corded

Corded drills are best suited for heavy-duty applications. There are a few things to keep in mind when looking for one. Some features of cordless drills (torque and speed) are similar to those of corded drills, but you must also consider:

- Power: In terms of watts, a corded drill is powerful. The more wattage a drill has, the more powerful it is.

- Special Direct systems: are designed to increase the hammering force.

Whatever type of drilling machine you choose, whether cordless or corded, the most important thing is that you find the right tool for the job at hand.

Trinkle Enterprise Co. Ltd. is a Taiwan-based professional steel structure construction related to steel processing equipment and tools manufacturer that specializes in providing tools, equipment, and supplies you need where, when, and how – including power tools from trusted Trinkle suppliers. Reach us to discuss your needs!