News

NewsDrilling Machines and Milling Machines – Do you know the Differences?

Drilling Machines and Milling Machines – Do you know the Differences?

Drilling devices, are fixed style drills that may either be attached on a stand or bolted in order to the floor or perhaps workbench. The speed may be changed in these machines by simply manually moving the belt across a new pulley arrangement.

Drilling machines can supply its customers numerous advantages. Firstly, the lever provides typically the operator an extensive mechanical advantage. As it is set to a table, this enables the vice or grip to be applied to position and even safe the function piece generating the particular operation a lot a lot more precise. In inclusion to this, the angle of the particular spindle is fixed relative to typically the table, allowing slots to be drilled accurately and over and over again.

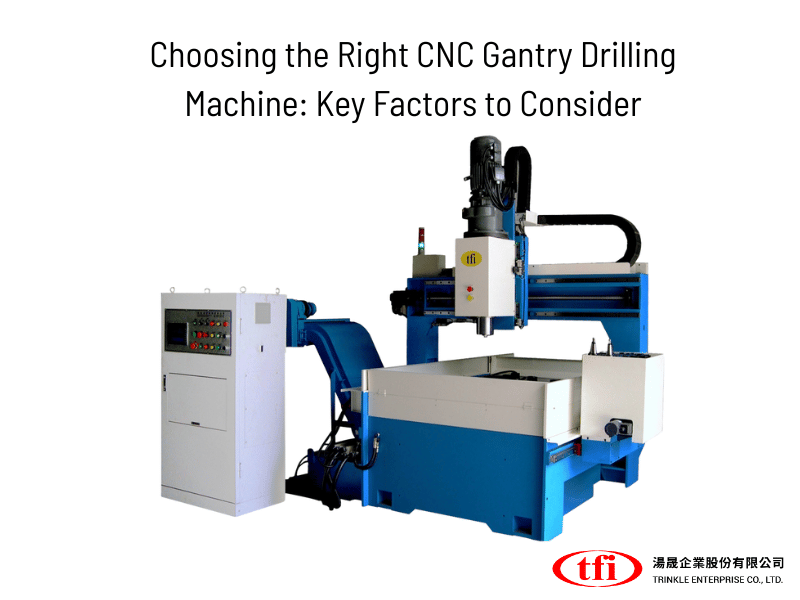

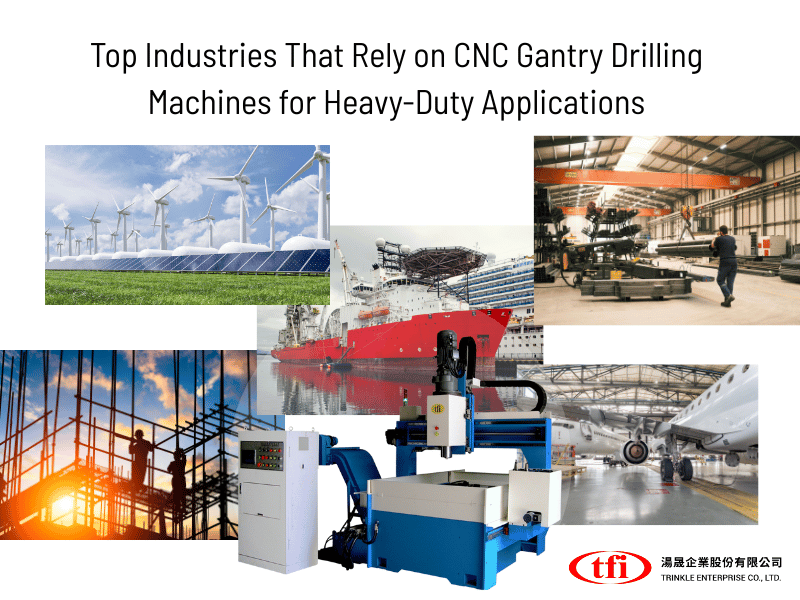

Most modern day equipment are technically automated with the aid of computer system numerical manage (CNC) technology. Since of CNC drilling machine can become programmed to create precise final results, constantly. In distinct, COMPUTER NUMERICAL CONTROL drilling machines are helpful for design hole drilling, compact hole drilling in addition to angled holes. Going machines are often made use of for randomly workshop tasks such as sanding, focusing or polishing, and a variety of some other rotating accessories inside the chuck.

Milling machines differ to be able to drilling machines inside a selection of methods. These machines happen to be made use of for reshaping metal and some other strong supplies. Milling machines come in two varieties, both horizontal or up and down. This appertains to the place of the trimming tool spindle. As opposed to drilling exactly where the particular piece is standing and the drill moves vertically on the material, milling likewise requires movement associated with the perform piece against the revolving cutter.

In a comparable way to going machines, milling equipment could be manually operated, mechanically computerized, or digitally automated CNC. Milling devices can be made use of to carry out there a quantity of tasks. Some of these types of are really complicated, for example, drilling, die sinking, rebating, routing, etc.

Because with drilling machines, several modern day milling machines are manipulated by a laptop. This delivers these a lot more flexibility. When this kind of is combined with the proper accessories conical tools or a ball nose cutter, it may considerably increase their precision with no influence on rate, offering a price — effective alternative to be able to most flat-surface hand-engraving perform.

Previously, these types of machines had been extremely expensive to obtain in addition to operate but together with the drop in the value associated with computer technology it has created these people a great deal additional inexpensive and accessible. This has permitted additional firms to take advantage of this technologies, enhancing competition in typically the industry.

- Products

- Plate Drilling Machine

- Rail Type Bridge Plate Drilling Machine

- Beam Line Drilling Machine

- Laser Marking Machine

- Beam line stamper

- H-Beam Scallop & Beveling machine

- Plate beveling machine

- Auto Arm Welder

- Pipe Notcher

- Drill Grinder

- Magnetic Core Drilling Machine

- Remolift

- Shear Wrench

- H-Beam Rotater