News

NewsThe Modern Landscape: Trinkle Enterprise Co., Ltd. and Advanced Drilling Solutions

The Modern Landscape: Trinkle Enterprise Co., Ltd. and Advanced Drilling Solutions

In the grand tapestry of human history, the drilling machine stands as a testament to innovation, ingenuity, and the relentless pursuit of efficiency. The evolution of drilling technology is a fascinating journey that spans centuries and traverses diverse cultures. Join us as we unravel the origins of the drilling machine, a tool that has played a pivotal role in shaping the way we manipulate materials and construct the world around us.

Early Beginnings: Hand-Driven Drills

The roots of the drilling machine can be traced back to ancient civilizations where the earliest form of drilling was a manual and labor-intensive process. Hand-driven drills, consisting of a simple rotating shaft with a sharpened point, were employed by ancient craftsmen and artisans. These early drilling tools were primarily used for woodworking and crafting small holes in various materials.

Ancient Egypt: Bow Drills and Beyond

In ancient Egypt, ingenuity took center stage with the introduction of the bow drill. This innovation allowed craftsmen to apply rotational force more efficiently, enhancing their ability to drill holes with greater precision. The bow drill featured a spindle with a drill bit attached to one end, and a bow that, when moved back and forth, rotated the drill bit. This marked a significant leap forward in drilling technology during the ancient world.

The Roman Influence

The Romans, known for their engineering prowess, contributed to the evolution of drilling technology. Archaeological evidence suggests the use of tubular drills powered by hand or animal-driven mechanisms. These drills were utilized for various applications, including mining and the creation of water wells. The Romans' emphasis on practical engineering laid the groundwork for later developments in drilling machinery.

The Middle Ages: Wind and Water Power

As the Middle Ages dawned, the quest for more efficient drilling methods continued. Water wheels and windmills emerged as sources of power for driving primitive drilling machines. These machines were often employed in mining operations, enabling the extraction of valuable resources from the earth. The utilization of natural energy marked a notable shift toward mechanization in drilling processes.

The Industrial Revolution: Steam Power and Precision

The true revolution in drilling technology occurred during the Industrial Revolution in the 18th and 19th centuries. Steam engines became a driving force behind drilling machines, providing a level of power and efficiency previously unimaginable. The development of the steam-powered drilling rig transformed industries such as mining and construction, making it possible to bore deeper and larger holes more rapidly.

Electric Power and the Birth of Modern Drilling

The late 19th and early 20th centuries witnessed a seismic shift with the advent of electric power. Electric motors replaced steam engines, offering a cleaner and more controllable source of energy. This transition paved the way for the birth of modern drilling machines, which became more compact, versatile, and accessible across various industries.

The Rise of Specialized Drilling Machines

As technology advanced, drilling machines evolved into specialized tools tailored for specific applications. Radial arm drills, bench drill presses, and portable electric drills became commonplace in workshops, factories, and construction sites. These machines, often powered by electricity, allowed for greater precision and efficiency in drilling operations.

Computer Numerical Control (CNC) and Beyond

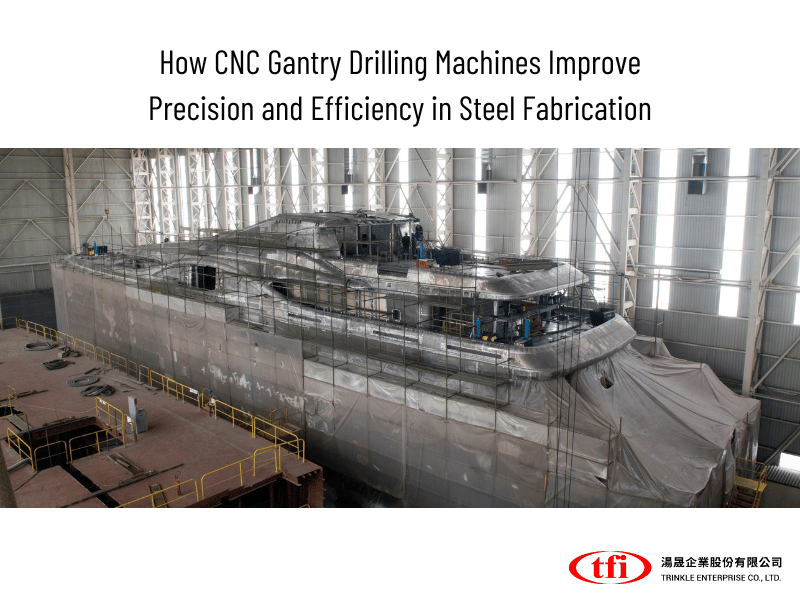

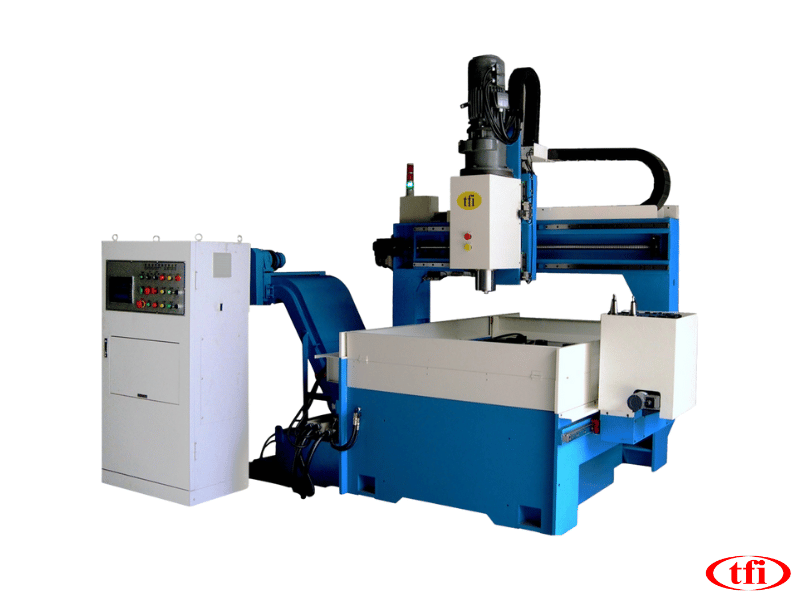

The latter half of the 20th century ushered in the era of Computer Numerical Control (CNC) drilling machines. This transformative technology integrated computers into the drilling process, enabling automated and highly precise drilling operations. CNC drilling machines revolutionized industries like aerospace and manufacturing, where intricate and accurate hole patterns are critical.

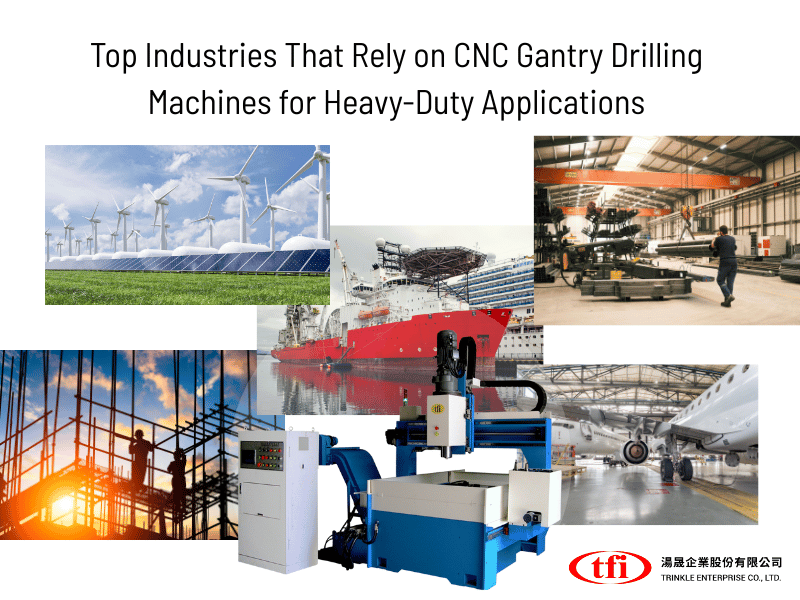

The Modern Landscape: Trinkle Enterprise Co., Ltd. and Advanced Drilling Solutions

As we step into the 21st century, the drilling landscape is characterized by cutting-edge technology and specialized solutions. Among the innovators in this field is "Trinkle Enterprise Co., Ltd.," a company at the forefront of providing advanced drilling solutions. With a commitment to excellence and a focus on meeting the evolving needs of various industries, Trinkle Enterprise has become a name synonymous with precision and efficiency.

Explore the range of drilling solutions provided by Trinkle Enterprise: Trinkle Enterprise Products.

- Plate Drilling Machine: Precision Redefined: Trinkle Enterprise's Plate Drilling Machines are a testament to the company's dedication to precision engineering. These machines are tailored for tasks that demand utmost accuracy, such as drilling holes in metal plates for aerospace components, automotive parts, or structural elements in construction.

- Rail Type Bridge Plate Drilling Machine: Bridging the Gap in Efficiency: For larger-scale operations, Trinkle Enterprise offers Rail Type Bridge Plate Drilling Machines. These machines are designed to handle the drilling needs of massive workpieces, such as those found in bridge construction. The rail type design provides stability and precision across the entire length of the workpiece, ensuring consistent and accurate results.

- Beam Line Drilling Machine: Streamlining Structural Fabrication: In the construction and manufacturing of steel structures, precision is non-negotiable. Trinkle Enterprise's Beam Line Drilling Machines are engineered to meet the challenges of structural fabrication. These machines are equipped to efficiently drill holes in beams, columns, and other structural components, contributing to the integrity and safety of the final structure.

The Future of Drilling: Advancements and Innovations

Looking ahead, the future of drilling machines promises even greater advancements. As industries continue to push the boundaries of what's possible, Trinkle Enterprise remains at the forefront of innovation. The integration of robotics, artificial intelligence, and data analytics is poised to redefine the capabilities of drilling machines.

- Robotics in Drilling: Automation for Efficiency

Automation is a key driver of efficiency in modern manufacturing. Robotic drilling systems, integrated with CNC technology, are becoming increasingly prevalent. These systems can perform intricate drilling tasks with speed and precision, reducing the need for manual intervention and enhancing overall productivity.

- Smart Drilling with Data Analytics

The era of smart manufacturing has ushered in a new wave of possibilities. Drilling machines equipped with sensors and data analytics capabilities can provide real-time insights into the drilling process. This not only ensures quality control but also allows for predictive maintenance, minimizing downtime and maximizing operational efficiency.

- Sustainable Drilling Practices

With a growing emphasis on sustainability, the drilling industry is exploring eco-friendly practices. Trinkle Enterprise, in line with this trend, is dedicated to developing drilling solutions that are energy-efficient and environmentally conscious. This commitment reflects an awareness of the global need for responsible manufacturing practices.

Conclusion: Trinkle Enterprise and the Continuum of Drilling Excellence

As we reflect on the history and evolution of drilling machines, it becomes clear that Trinkle Enterprise Co., Ltd. has emerged as a key player in shaping the present and future of this industry. Their commitment to precision, efficiency, and innovation positions them as a reliable partner for businesses across various sectors.

To explore the full range of Trinkle Enterprise's drilling solutions and stay updated on the latest advancements, visit Trinkle Enterprise Products. As drilling technology continues to evolve, Trinkle Enterprise remains dedicated to providing state-of-the-art solutions that meet the dynamic needs of modern manufacturing and construction.